Easier material feeds thanks to roller conveyors

Optimise the sawing process by adding accessories

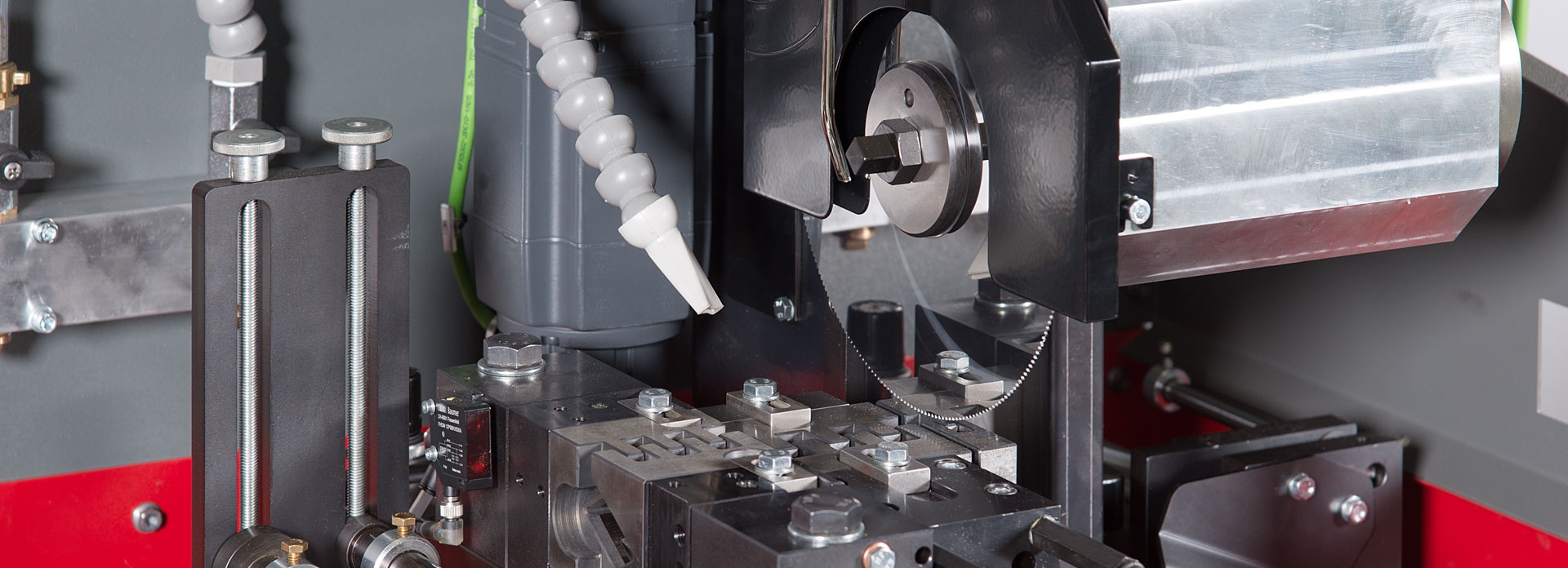

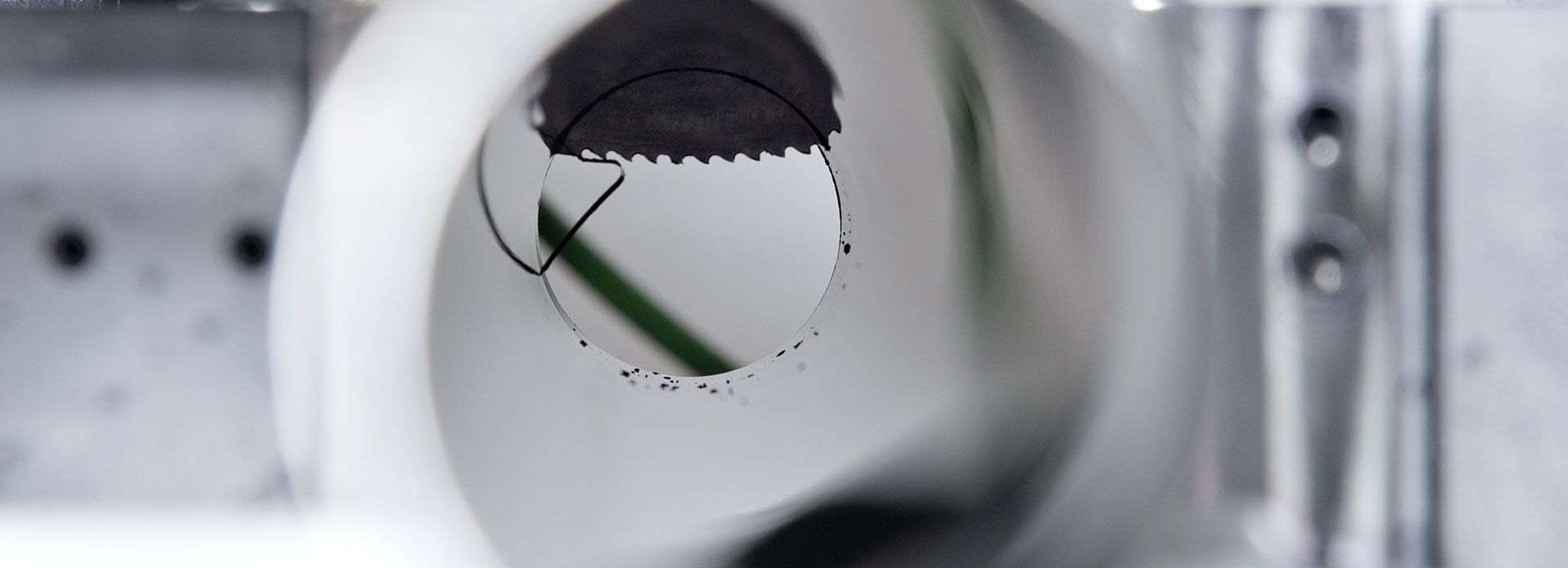

If you decide to connect a roller conveyor to your automated sawing machine, it becomes easier to feed your semi-finished goods into the machine, and to obtain more-precise sawing results. The materials, such as rods, pipes, profiles or pipe bundles, are optimally supported, and can be slowly and carefully processed. In addition, the roller conveyor can be adjusted to various materials so that you can process various dimensions and shapes.

A roller conveyor can adjust to sawing materials

Basically, two different forms are integrated in our roller conveyor. Feed can be individually adapted to material thanks to the built-in prism roll. The prisms can be placed at two heights: If the prism roll is lowered, the material runs onto flat rollers; and the material to be processed can be larger. The roller conveyor height can be manually set over the threaded spindle. Thus, no tool is needed. You have a clamping lever which greatly accelerates the work process. 4 to 36 pipe bundles can be processed.

Put together a custom solution with Rohbimax AG

Usually, we offer a roller conveyor for standard lengths from 2, 3, 4, 5 or 6 m. These material lengths are commercially available and easy to process. Individual sizes can also be accommodated. We can build a roller conveyor for you with much greater total lengths and can put together an interplay of prism and flat rolling to exactly meet the requirements of the material that you would like to saw. We would be pleased to visit your operation in order to develop a first impression of the spatial dimensions and products. Of course, Rohbimax is also at your side after the purchase of your automated sawing machines with accessories, for repairs, overhauls and software updates.