Metal circular saws for all common metals

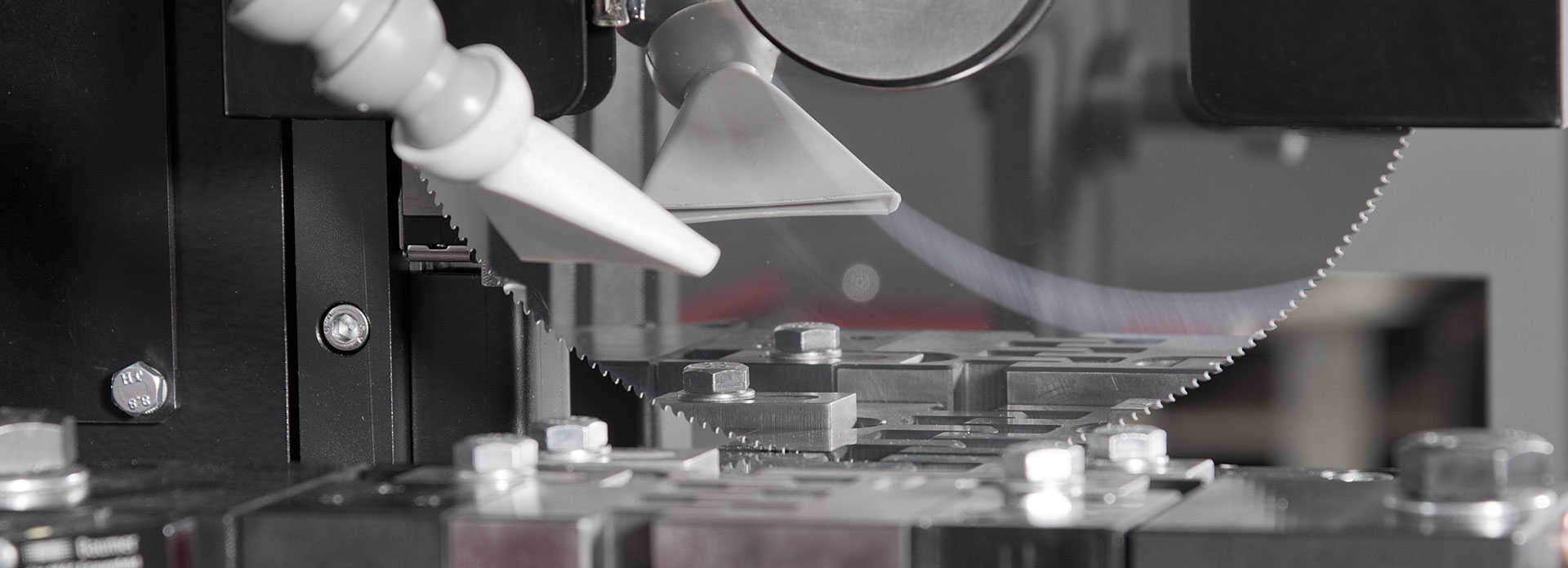

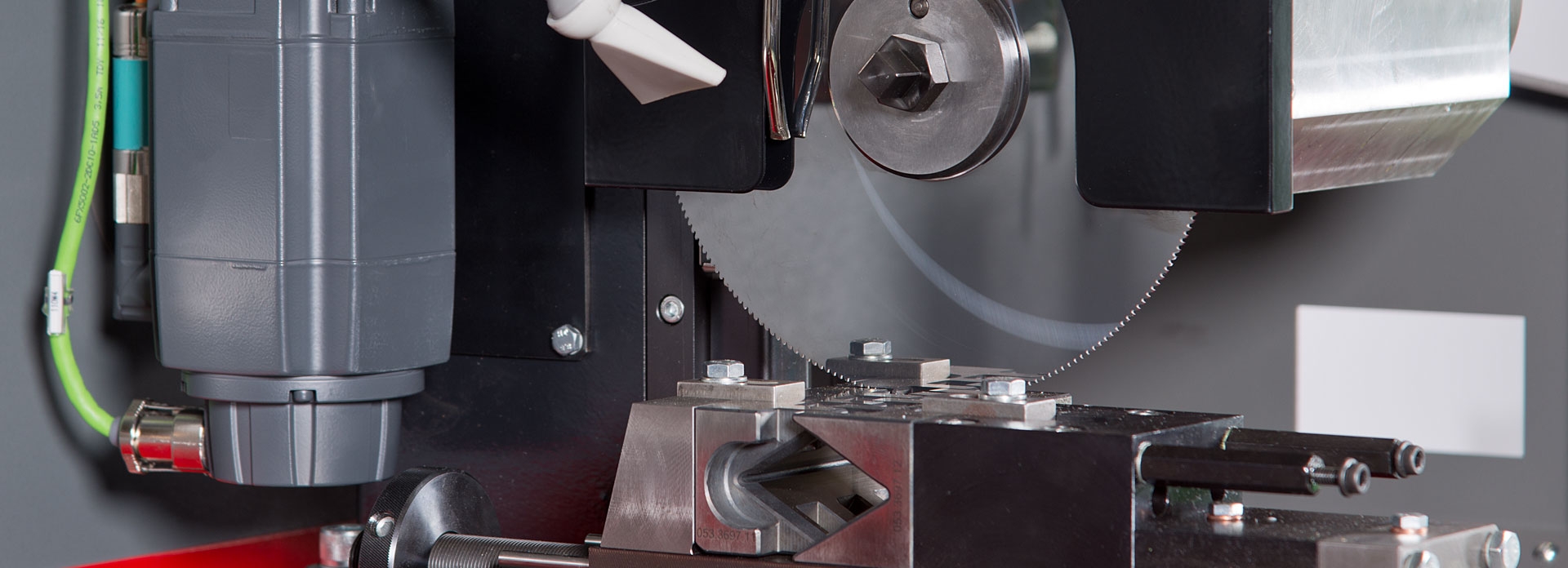

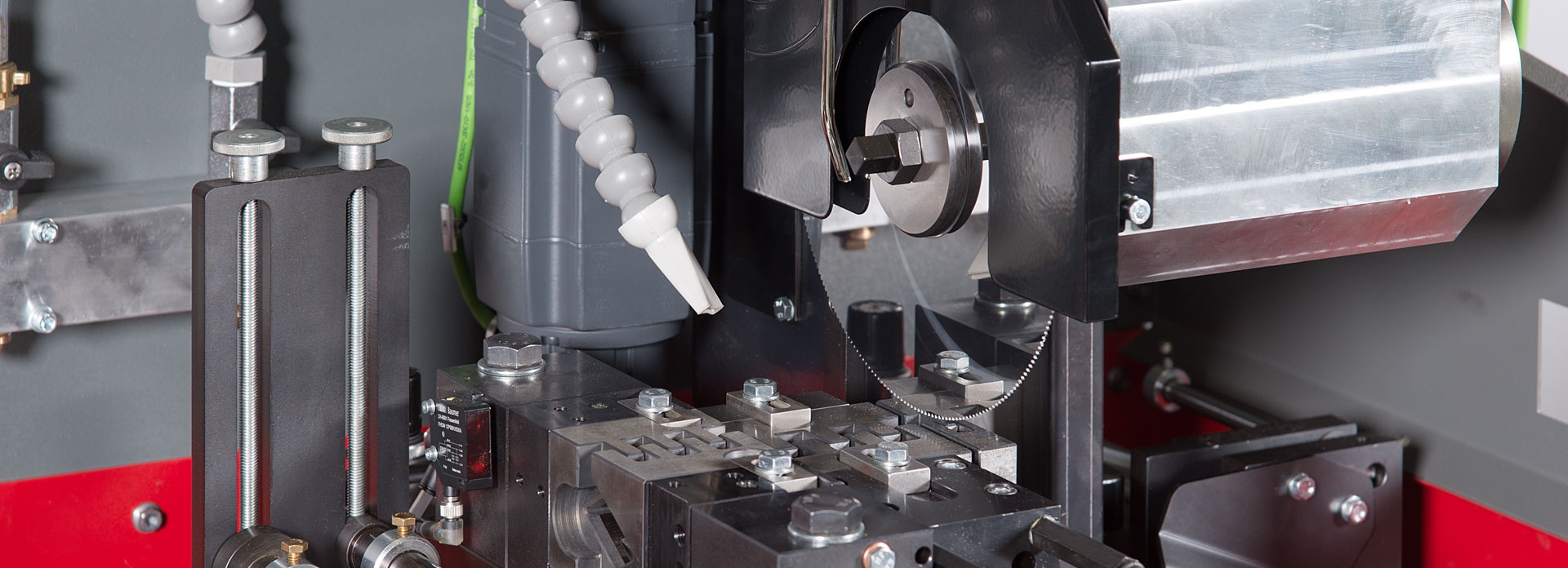

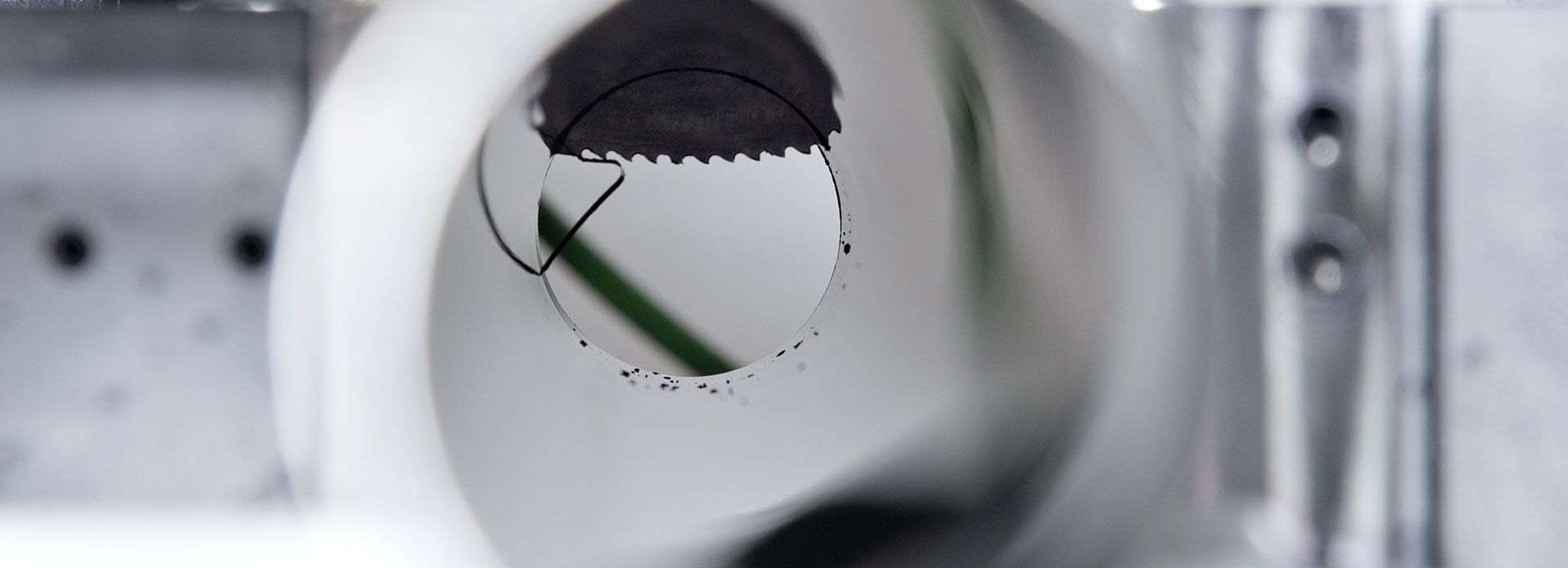

Rohbimax metal circular saws are designed to cut round pipes, square pipes and profiles with the smallest to mid-sized diameters from 0.6 to 60 mm. We work with high-alloy steel, titanium, chrome-nickel steel, non-ferrous metals such as copper, brass and aluminium or precious metals, such as silver and gold. Our automated sawing machines are relied upon for their high precision and great production performance. Thanks to the jaws which are prepared for customers’ needs, even rods with complicated outside geometries and thin walls can be securely sawn. Using prism jaws, pipes can additionally be cut in groups – this increases performance. Metal circular saws can separate precisely to 0.02 mm. They protect sawblades in high-performance mode, while creating low-burr and burr-free cuts that rarely require re-working.

Why a metal circular saw from Rohbimax AG?

We can meet tough requirements for cycle time, precision and product quality. Our machines are selected by many well-known manufacturers, including Siemens and Bosch. Our RKA 92.600 metal circular saws have many advantages:

Gentle, automated production

A hydropneumatic drive developed by Rohbimax ensures an automatic control of stroke rates. It controls the spindle with a proportional valve with high precision. The saw stroke follows programs during the entire process. After long work intervals, high cycle times or heated oil in the system, one can still count on the system to provide precise cuts which meet requirements, while being gentle to the sawblades.

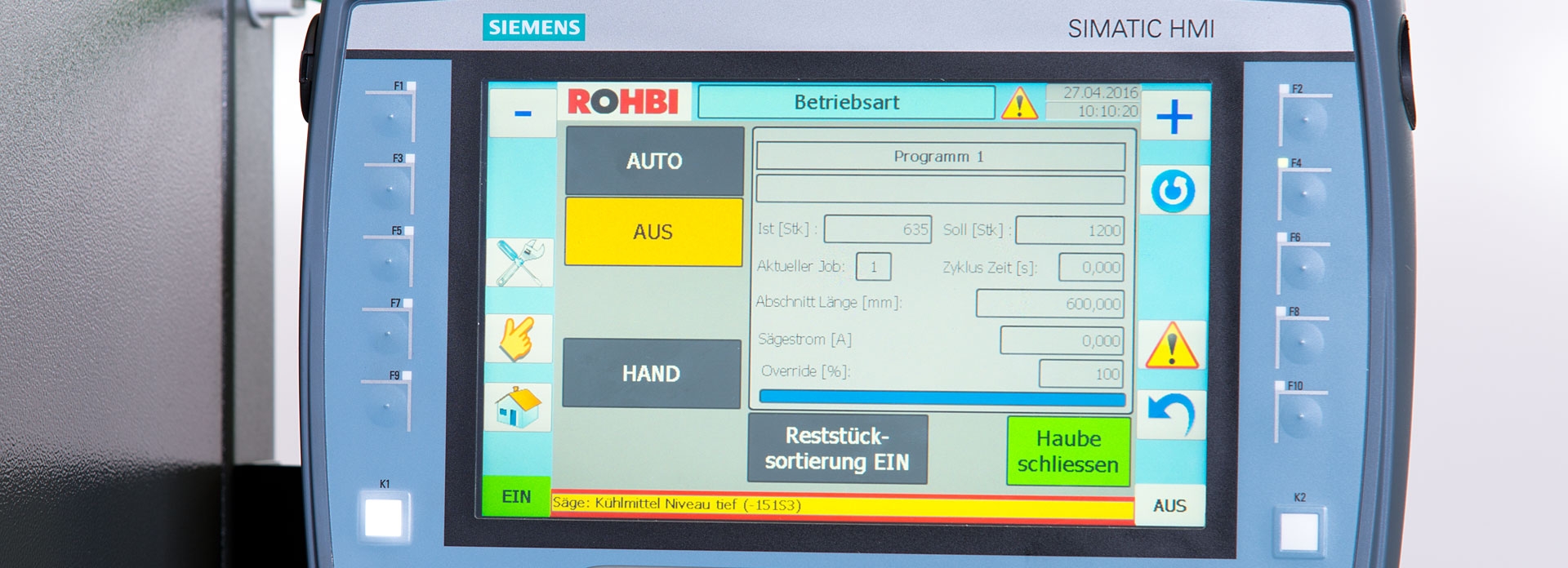

Easier controllability

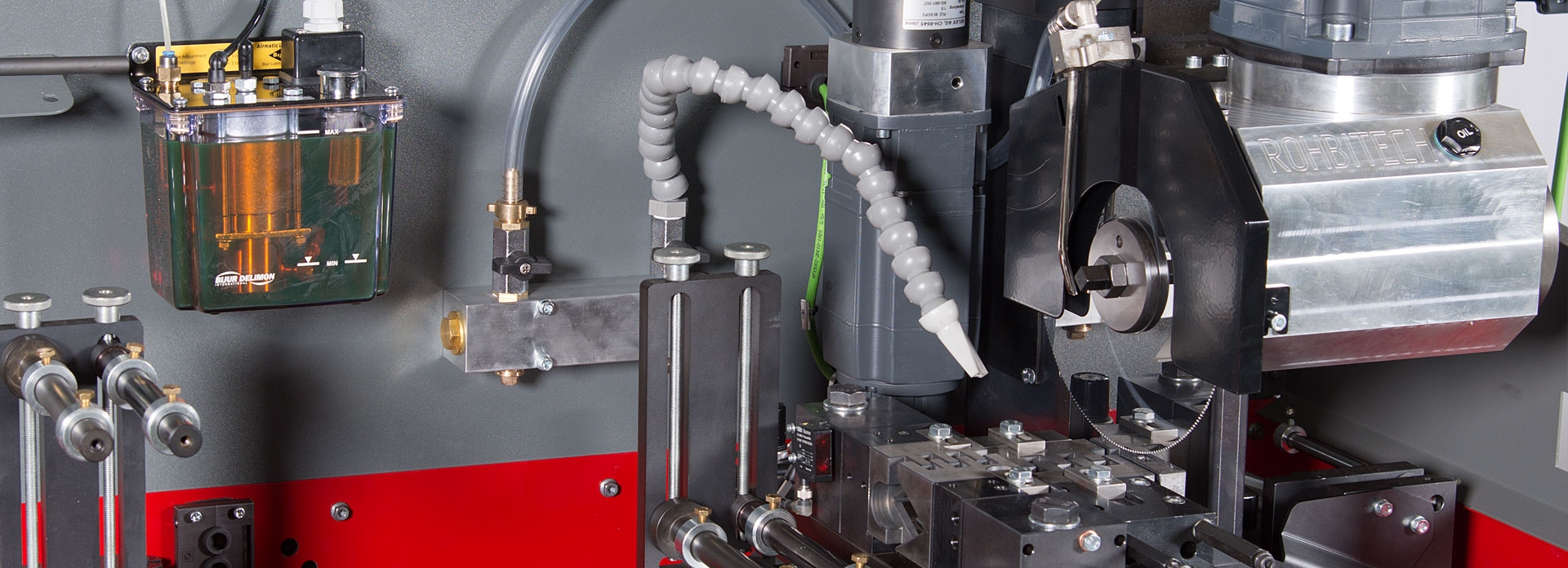

You receive all information and control the system from every position using a portable control panel with touch functions and a colour display. At the same time, the teach-in procedure can define five different speeds per saw cut. The material is positioned using precise linear guides with direct stroke lengths of up to 600 mm in the material feeder. Using picking, lengths up to 9999 mm can be fed. The material feeder is driven by an AC servomotor and a ball bearing spindle. The guide is lubricated by a pneumatically actuated centralised lubricating system.

Customer orientation

Customers do not simply receive standard metal circular saws from us. Each machine from our company is exactly configured to meet customer needs. Handling, the shape of the jaws, lighting, colour, execution of the spindle equipment, feed of specific materials and geometries, the lubrication system and much more are specified by the customer. Rohbimax finds the right solutions together with our customers. This ensures customers’ satisfaction over many years. This fulfils all automated sawing machine requirements.

Modular systems

You can extend your metal circular saw at any time with an extensive offering of peripheral devices to further automate your production. Look at our bar feeder.

Swiss high-quality product

We are proud to carry the quality seal ”Made in Switzerland”. This assures the use of high-quality materials, manufacturing quality and long-lived products.

Network

With Rohbimax, customers benefit not only from our extensive services, such as remote maintenance, spare parts inventory, personal advice and repair services, but also from our large network which brokers new customers for outsourced sawing.

Order metal circular saws and rely on the market leader’s custom solutions

We are happy to invite you to a personal discussion to provide additional information. We can then start designs based on your requirements to create custom metal circular saws. Once we’ve manufactured the system at our facility, we test it based on your requirements. We provide you short delivery times and service which extends far beyond pure sales. You can immediately start production after assembly, commissioning on-site and training your staff. Of course, we are happy to answer your questions, maintain and repair your machines, and send you parts from our large spare parts warehouse.