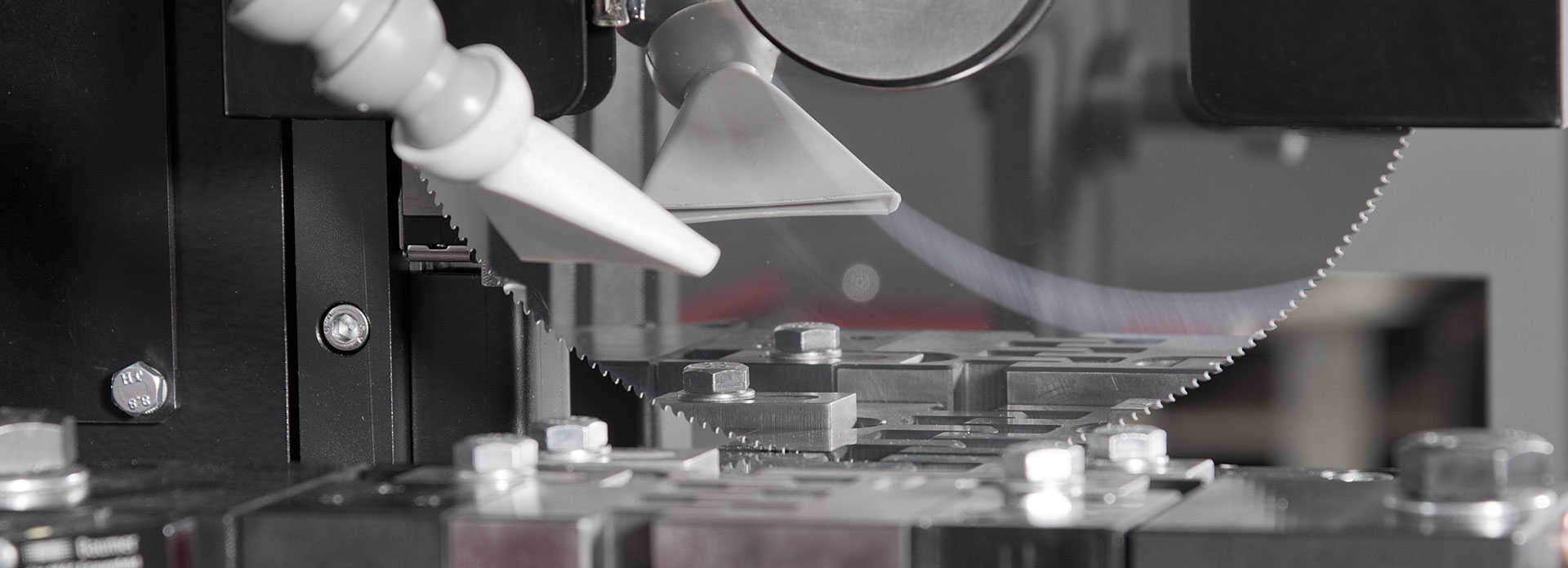

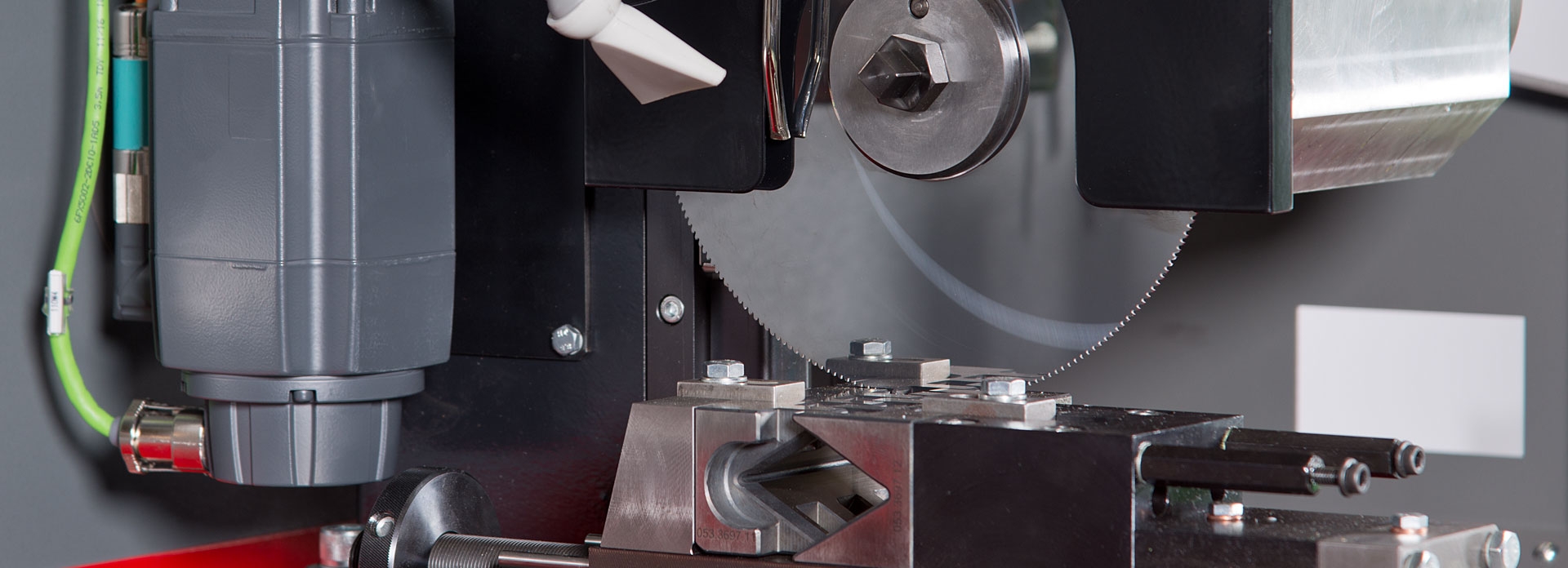

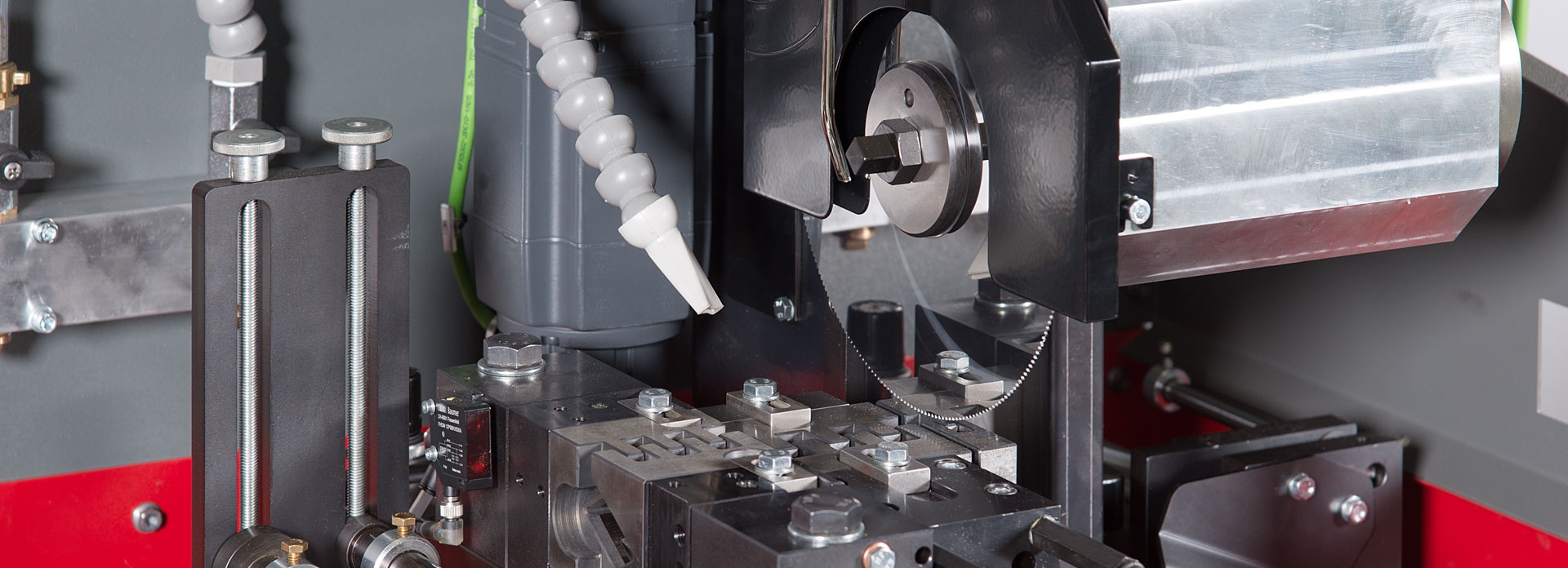

The type and quality of a sawblade are decisive for optimal sawing result quality and are selected depending upon the materials to be sawn. Rohbimax AG offers two different automated sawing machine series, the RKA and KTC models. The classic RKA precision saw from Rohbimax can be fitted with an HSS or solid carbide circular sawblade. KTC machines can be supplied with an HSS or solid metal circular saw guides as well as with carbide-tipped teeth.

Technical data about our types of sawblades

We offer solid carbide circular saw guides in two different versions: as solid carbide or carbide-tipped. As you can guess from the name, the solid carbide circular sawblade consists of solid carbide, and the other has carbide-tipped teeth. Sawblades made of solid carbide usually are 0.4 to 1.2 mm thick, and have a diameter between 80 and 200 mm. The HSS circular sawblade is usually 0.8 to 3.5 mm thick, with a diameter of 175 to 400 mm. Of course, Rohbimax can vary the size and number of teeth to customer needs and depending upon the workpieces to be processed. In addition to these two types of circular sawblades, you also have the option to order carbide-tipped disposable circular sawblades with a thickness of two to 2.6 mm, and a diameter of 250 to 360 mm.

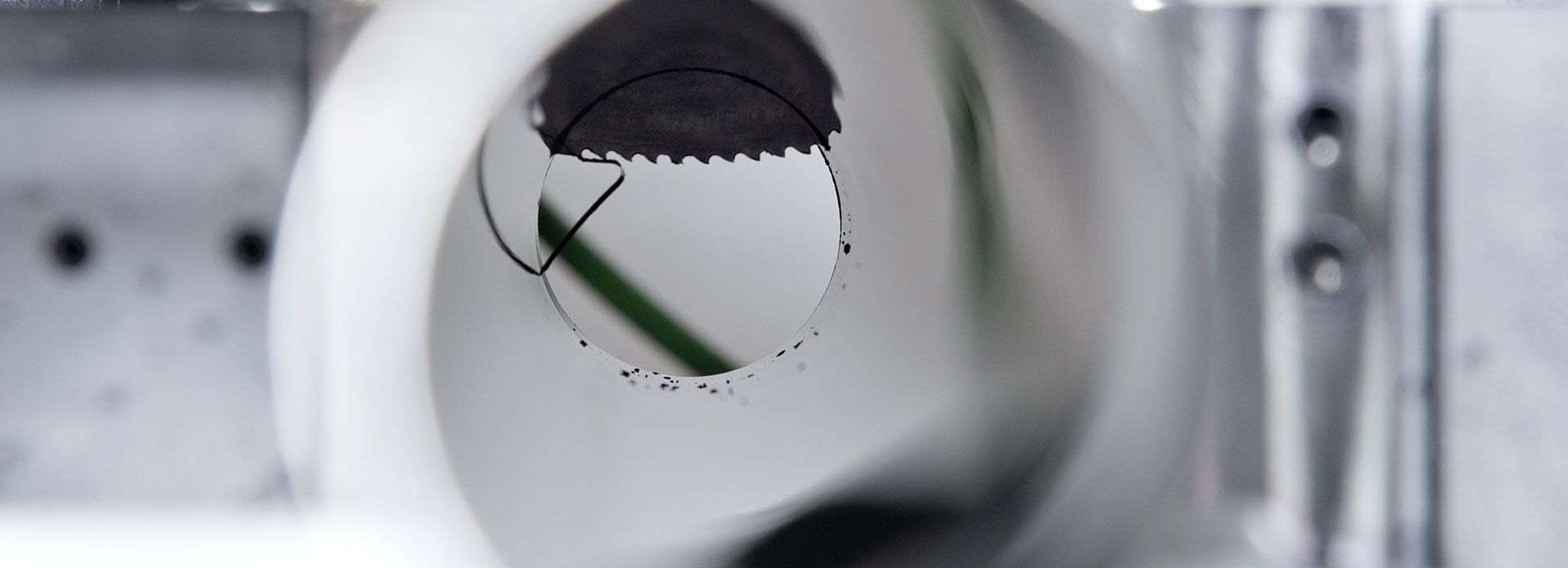

The quality of a sawblade is decisive for the sawing results

The basis of optimal sawing results is not only the quality of the blade, but also the high quality of the round and flat run. These requirements are fulfilled with Rohbimax AG sawblades. Thus, our sawn parts have a very tight length tolerance of +/- 0.02 mm. In addition, they are very low- to no-burr. A high-quality sawblade is worth it, as you can easily and precisely cut pipes with very thin walls. Thus, a high-quality sawblade can also save costs, as its high precision makes it practically unneeded to perform additional processing on a workpiece.